Structural Investigations

Excel Building Surveying Ltd have recently been commissioned to complete a number of structural investigations. The first included determining the make-up of a post-tensioned concrete framed multi-storey office block in London prior to demolition. This included scanning selected members using Proceq GPR Live, cutting 30no core samples with hydrostatic diamond drilling equipment, collecting 30no bulk concrete dust samples for analysis of chloride Ion and HACC content, Schmidt hammer testing, concrete resistivity testing, measuring the depth of carbonation using Phenolphthalein indicator solution, measuring the depth of concrete cover to reinforcement using Proceq Profoscope cover meter, measuring exposed bars by digital calipers. The second involved completing an inspection of a number of balconies in Bournemouth. Work was requested following spalling of a number of balcony soffits due to expansive freezing of handrails. Work involved hydrostatic diamond coring, tap-hammer test, half-cell testing, collecting bulk dust samples for chloride Ion analysis, measuring cover and carbonation depths and reinstating with acrylic reinforced lightweight mortar. The third were completed to a carpark in York. The work involved a chain drag survey (to determine defects audibly), hydrostatic diamond coring, scanning using Proceq GPR Live, half-cell testing using Proceq Canin wheel, collecting graduated concrete dust samples. Laboratory analysis included microscopic inspection and petrographic analysis of core samples, chemical analysis of dust samples for chloride Ion concentration. The depth of cover and carbonation was also measured at each sample position. The surveyor completed a visual appraisal and limited measured survey and report. Further structural investigations were completed to a London warehouse and involved scanning, dust sampling and coring a portal frame from a 15m cherry picker operated by the IPAF qualified surveyor. Work was requested as part of due diligence prior to proposed purchase, change of use and potential addition of mezzanine floors. Core samples were tested in compression at our partner UKAS lab.

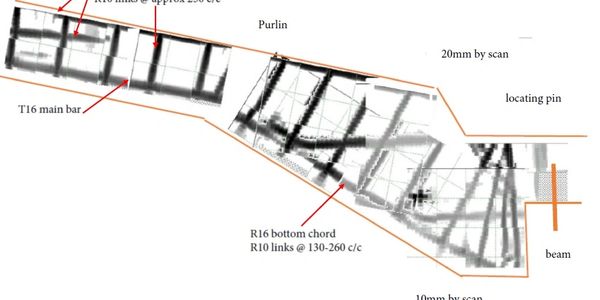

Portal frame scan data collected using Hilti Ferroscan electromagnetic scanning equipment.

Excel Building Surveying personnel have over 15 years’ experience completing structural investigations from domestic properties to London banks, offices, rail and road bridges, schools and the like.

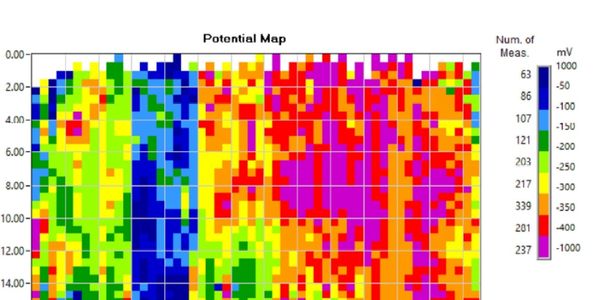

Half-cell potential map of a 27m x 16m slab. Each pixel shows the half cell potential of a 500mm x 500mm square. The extremely high values show areas with obvious defects. The blue area is a coated roadway with no obvious defects.

Please feel free to call Paul Gatland on 07850 494947 to discuss in confidence any structural investigation requirements you may have.