other varied projects

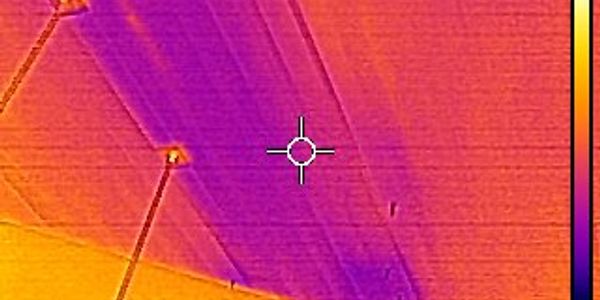

Excel Building Surveying Ltd have recently been commissioned to complete a number of investigations, surveys and tests including thermal imaging surveys, slip resistance testing, screed level survey, fluorescent dye testing, pinhole testing and planning applications. Thermal imaging has been completed in order to gain BREEAM points for façade inspection for heat loss. Inspections were carried out using Flir Ex8 thermal imaging camera in association with confirmatory ambient and surface temperature readings taken using Protimeter Moisture Meter (MMS2). Further inspections were completed with the Flir Ex8 to locate the extent of water presence within a metal sheet roofing system. Having located colder troughs (due to be water filled), water soluble fluorescent dyes were then introduced externally to determine the areas of potential water ingress. Fluorescent dye was noted internally some time later and the defects repaired with lead flashing. Slip resistance testing was completed to a basement carpark in a new-build block of flats in London. Testing was required to confirm that surface coatings were suitable for application across the entire estate. Tests were completed on treated and adjacent untreated areas for comparison purposes. The BRE skid resistance/ pendulum test equipment was set up, levelled using the bubble as a guide, and the test rig height adjusted to ensure that the rubber shoe was in contact with the substrate for between 125mm and 127mm as specified in the equipment usage guidance. The indicator arm was also adjusted to ensure that it reached “0” when swung freely (without the shoe contacting ground). 3no. tests were completed along the grain of surface tamp finish, 3no perpendicular to the grain and 3no diagonal to the grain. The sets of tests were completed in a dry condition followed by wet condition on both treated and untreated test positions. The tests passed the client`s pass criteria of 40 and the coating was therefore approved. A screed level survey (measure of property IV- Concrete Society Technical Report 34) was completed to a new-build coffee shop in Northampton. A self-levelling rotating Leica lazer was set up on a tripod and measurements taken at 3m nodes using a traditional surveyors staff. The difference in height between the nodes was found to be <10mm at all positions and the screed therefore considered to meet floor classification FM3 in accordance with Concrete Society Technical Report 34. Excel was asked to act as a planning agent and to complete a planning application on behalf of the local council for change of use of a council owned building within a short time frame. Excel were able to complete the process and await the outcome.

Internal thermographic view of metal roof showing temperature variations between adjacent sections

Excel Building Surveying personnel have over 15 years’ experience completing a vast array of testing and investigations across all sectors and building types for a range of clients.

BRE pendulum test equipment used to determine the slip resistance of surface finishes

Please feel free to call Paul Gatland on 07850 494947 to discuss in confidence any testing or investigation requirements you may have.

FLOOR LEVEL TESTING TO CSTR34

Excel Building Surveying Ltd have recently been commissioned to complete floor level surveys of a number of varied properties to confirm compliance with Concrete Society Technical Report 34 (CSTR34) table 3.1. Testing was completed to measure properties E & F with regard to floor classes FM3 and FM4. A 3m grid was measured using a 1m surveyors wheel and marked in chalk on the various floors. Areas covered by materials, plant, work stations etc are ignored. A rotating lazer level is set up on a tripod and levels taken at the 3m grid points (nodes). A property II "F" meter is then pulled along a suitable number of node lines to determine the change in elevational difference over 300mm measured continuously. Results are analysed to determine 95% of measurements and this figure is then used to confirm compliance or otherwise. The pass criterion may be critical particularly if the floors are to be used for high racking and fork lifts and if the buildings are part of safety critical infrastructure as recently completed by Excel Building Surveying. In addition, we have tested a number of the same floors for slip resistance using BRE Pendulum slip resistance test equipment and resistivity using Proceq Resipod 4-pin Wenner probe.