non-destructive testing

Excel Building Surveying Ltd have been commissioned to complete NDT at various sites across the UK and Europe to determine the condition of stone, concrete and embedded reinforcement. Test regimes included half-cell potential, concrete resistivity, ultrasonic pulse velocity (crack depth determination), electromagnetic (Hilti Ferroscan, Proceq Profoscope) and radar (Proceq GPR Live) scanning, hammer testing, chain drag surveys, core and dust sampling, pull-off and pull-out testing, internal fracture tests and most importantly, though often overlooked and under-valued, visual assessments of condition and type of concrete as part of wider structural investigation works.

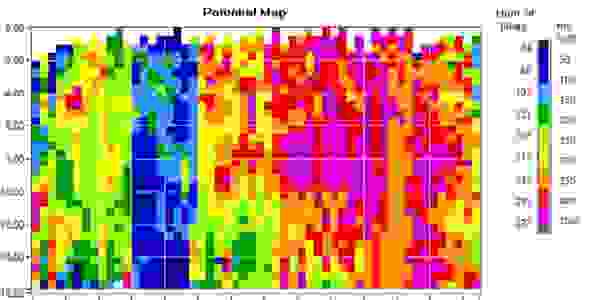

Half-cell potential testing can provide a guide to the positions of likely reinforcement corrosion by measuring the electrochemical activity of concrete. The test equipment requires connection to embedded reinforcement in order to complete a circuit. The potential for active corrosion can be measured (in mV) on a voltmeter connected to the reinforcement and the concrete surface. Test node spacing, the presence of surface coatings and the half-cell material itself can all have an effect on the results. Both the test regime and interpretation of the results rely heavily on the experience of the surveyor/ engineer to provide useful, accurate results. Connection to reinforcement ordinarily requires a small breakout of the concrete. In order to minimise the extent of the breakout required, scanning is usually completed using a Proceq Profoscope electromagnetic cover meter. This is also used to measure the depth of concrete cover to reinforcement at each test node.

We have used ultrasonic pulse velocity (PUNDIT) test equipment on a variety of projects to determine the depth of cracking to stone (prior to carving of decorative statuary for Grade 1 listed property) and concrete at numerous sites including bridges, nuclear power stations, listed commercial buildings etc. Correct interpretation of the results is critical to inform decisions regarding purchase, repairs etc.

All of the sampling and testing techniques (in association with laboratory analysis of samples) may be used in conjunction to provide a comprehensive, detailed condition survey and report to provide confidence of the residual life expectancy, potential future maintenance requirements and general worthiness of any structure.

The half-cell potential of a 27m x 16m carpark slab measured using Proceq Canin wheel electrode. Each pixel represents 500mm x 500mm square.

Excel Building Surveying personnel have over 15 years’ experience of non-destructive testing ranging from bridges to nuclear power stations, domestic flats to universities, swimming pools, carparks, shopping centres, commercial floors, beams, columns etc.

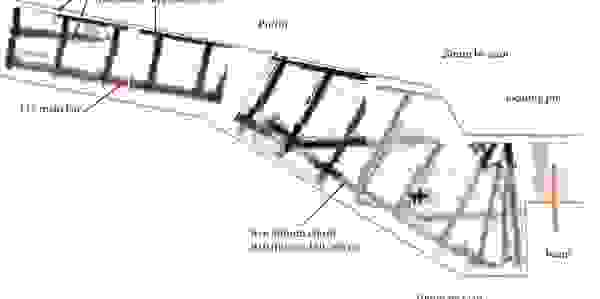

Results (following data interpretation) from Hilti Ferroscan showing reinforcement within a pre-cast portal-framed industrial unit. Results used to confirm load capacity of roof prior to over-cladding.

Please feel free to call Paul Gatland on 07850 494947 to discuss in confidence any non-destructive testing requirements you may have.